Family-run companies that span multiple generations all face a difficult challenge. They have to be aware of how their market is changing. If they just maintain the status quo, they risk losing their edge – and their customers. Evergreen Nursery was founded 150 years ago on 1 acre in scenic Sturgeon Bay, Wis. Today, it is Wisconsin’s largest wholesale nursery at 446 acres.

Family-run companies that span multiple generations all face a difficult challenge. They have to be aware of how their market is changing. If they just maintain the status quo, they risk losing their edge – and their customers. Evergreen Nursery was founded 150 years ago on 1 acre in scenic Sturgeon Bay, Wis. Today, it is Wisconsin’s largest wholesale nursery at 446 acres.

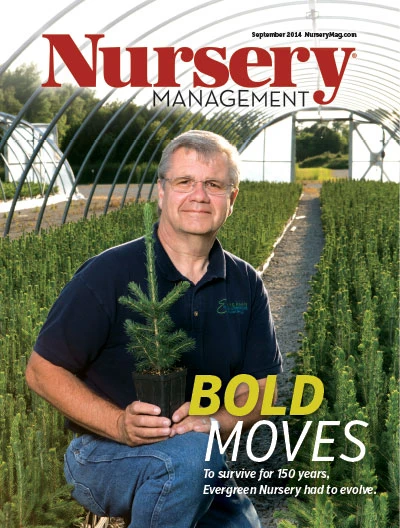

Ron Amos, the owner of Evergreen Nursery, says you have to accept that change is inevitable and do what you can to stay ahead of the curve.

“I’m a plant guy, and it’s an advantage and disadvantage,” Amos says. “The disadvantage being that you’ve got to be a business person, too. For me, the plants come naturally, the business doesn’t. So, you have to really do your homework on that, and I had to learn a lot. That’s always been my weak point – but we’re still in business, so I guess so far, so good.”

Amos was hired by Tom Pinney, whose family had run the nursery for four generations. Pinney was looking to help the nursery evolve from its roots as a field-grown, seedling business to a propagation nursery. Amos was brought on board to build that new facet of the business. He joined as a propagator in 1982, became vice president in 1995 and purchased the nursery in 2001.

“When I came here, we had a couple of old dilapidated greenhouses,” Amos says. “We built that part of the business, originally, just to supply ourselves with plants. Then, after about five years or so, we started really just selling the liners, so it became more of a liner nursery, not just a greenhouse operation that feeds their own fields.”

“When I came here, we had a couple of old dilapidated greenhouses,” Amos says. “We built that part of the business, originally, just to supply ourselves with plants. Then, after about five years or so, we started really just selling the liners, so it became more of a liner nursery, not just a greenhouse operation that feeds their own fields.”

Although the field operations still are a very important part of the business, the greenhouse-grown containerized liner portion has become the largest part of the nursery’s business.

Evergreen Nursery produces about three million liners a year. Its evergreens are grown from seed and hardwood cuttings. Birch liners are propagated using several different methods, including seed, cuttings and micropropagation. Deciduous shrub liners come from softwood and hardwood cuttings, and micropropagation. The nursery also grows hundreds of thousands of cranberry plant liners each year from hardwood cuttings.

The business may no longer mirror the one his great-grandfather founded, but that doesn’t surprise Pinney.

“Over time, from 1955 when I came back to the nursery to when I sold it in 2001, in those years, nothing remained the same,” Pinney says. “Everything changed at least once or twice or three times. You can’t be afraid to change, but you have to make change for a reason.”

From evergreens to cranberries

During the last 20 years, Evergreen has earned a reputation for propagation. Customers have asked to propagate a wide range of plants over the years that have required many different methods of propagation. That reputation was what opened the door to one of Evergreen’s most exotic innovations – its cranberry business.

About 10 years ago, Evergreen was approached by several growers for Ocean Spray – the fruit juice company. They wanted to know if Evergreen could propagate cranberries. This was before the recession started, but the nursery industry was contracting as a whole and Evergreen was contracting, too. Amos thought it seemed like a good opportunity to diversify, and soon enough, the nursery was propagating cranberry plugs and flats.

About 10 years ago, Evergreen was approached by several growers for Ocean Spray – the fruit juice company. They wanted to know if Evergreen could propagate cranberries. This was before the recession started, but the nursery industry was contracting as a whole and Evergreen was contracting, too. Amos thought it seemed like a good opportunity to diversify, and soon enough, the nursery was propagating cranberry plugs and flats.

This year, Evergreen will produce about two million cranberry plants. Evergreen is one of three growers in the U.S. that grow cranberry plugs. It was a bold move, and it signaled how far the nursery had come from its days as a conifer field grower.

“Ron is such a good grower and propagator that it really doesn’t matter whether he is growing birch, evergreens, or cranberries,” Pinney says. “He wasn’t afraid to jump into the cranberry market and learn about it, and frankly, I think that’s what allowed him to survive this last very tough downturn in the economy. If it wasn’t for his diligence and dedication to making these changes work and getting out and getting to know the cranberry market and its customers, besides learning how to grow them, I don’t think it would have survived.”

Evergreen grows cranberries in the same facilities that it uses for all of its other crops. After the cranberries are done, then Amos’ crew goes back to the softwood crop. Its softwood shrub cuttings will be in those houses once the cranberries are gone, so it gives them an extra use of those houses.

“The cranberry business filled in a niche,” Amos says. “The cranberries were out the door before we needed those houses for other things, so we just started double-cropping some of our houses. That was very helpful.”

While growing cranberries was a natural fit for Evergreen, there were still plenty of issues to sort through. Amos quickly had to develop a production protocol for the cranberries to ensure the varieties were kept separate.

While growing cranberries was a natural fit for Evergreen, there were still plenty of issues to sort through. Amos quickly had to develop a production protocol for the cranberries to ensure the varieties were kept separate.

“Every cranberry plant basically looks the same, and everything we’re working with is DNA-tested material that we have to keep track of, we have to keep disease free, and we have to keep clean,” he says.

Freeze frame

When Amos started at Evergreen, the nursery was entirely a field-grown, bare root operation. He and Pinney began working together on a flurry of changes, including a breeding selection program for birch that has yielded four patented varieties, the ongoing development of the nursery’s own liner trays and pots, as well the introduction of a freezing process.

The biggest change in the bare root segment of the business has been the freezing process. Perennial growers have been freezing plants for years, and Amos adapted the technique to work with the nursery’s 51-cell evergreen plugs.

Keeping the plugs at 28°F during the winter has a few advantages. It gives the nursery the leeway to ship to its customers at any time of the year. It also prevents winter burn on some plant material.

|

Full circle Tom Pinney’s strong reputation in the industry was one of the main factors that drew Amos to Sturgeon Bay. The great-grandson of George Pinney, who founded Evergreen Nursery, Tom Pinney was a past president of the American Nursery and Landscape Association and the International Plant Propagators Society’s Eastern Region. Amos had been involved with IPPS since the late ‘70s, and Pinney was the president of IPPS Eastern Region when Amos started with Evergreen. In high school, Amos worked at a garden center selling Evergreen Nursery evergreens. In December 2013, Amos was elected president of the IPPS Eastern Region for its 2013-2014 year. “There’s so much to learn, and it’s funny ‘cause, I’m 56 years old and I’m thinking, ‘Gosh, I’m becoming one of the old-timers that we used to make fun of.’” |

“Winter burn’s always an issue on spring harvest and material and that’s always going to be the way it is,” Amos says. “But we were able to take some sensitive species and harvest them all in the fall, put them in the freezer and they never have winter burn.”

Before Evergreen began freezing bare root evergreen plugs, the nursery used to have to wait until around April 1 to be able to get into the fields and start digging and shipping. Now, Amos says the nursery harvests about a third of its crop in the fall and places it in the 28° freezers.

The plugs are placed on racks that hold 10 or 12 trays then stacked on a shelving system in the basement of a barn that keeps things frozen. When the plants are thawed out, there is no root activity when they are planted. Amos stresses the importance of that.

“That plug is designed for one year,” he says. “If a plug starts to push in that tray that second year they will maintain the shape of that plug, and we don’t want that. You’re just training that plug or root system to be that shape. That’s another good reason for freezing, so we take our plugs and basically put them in an area where they will not flush in the spring until we’re ready for them.”

Mycorrhizal magic

One of the keys to the nursery’s success is right under your feet as you walk the rows. Evergreen’s field plants have heavy, multi-branched root systems because of a strong mycorrhizal fungi presence in the soil of Sturgeon Bay.

“We get very good infection into young liners, and we don’t apply it, it’s just natural,” Amos says. “Even in our three-and-a-half by five square liner that we use, I can pick out the plants that have heavy mycorrhiza because of the color and everything.”

The beneficial fungi grow in association with the plant roots, and increase the absorptive area of the plants. There are a few tricks to keeping the helpful fungi around. Phosphorus-rich fertilizers suppress the mycorrhiza, so it’s important to manage phosphorus levels.

“That mycorrhiza’s going with our plants to our customers, and hopefully they’re getting good growth, and I think that’s why our plants are so popular, too,” Amos says.

.jpg) Another benefit to Evergreen’s Wisconsin location is that the cool growing season and relatively low humidity is perfect for rooting and growing cuttings.

Another benefit to Evergreen’s Wisconsin location is that the cool growing season and relatively low humidity is perfect for rooting and growing cuttings.

“Our summers are very Pacific Northwest,” Amos says. “We rarely get a 90 degree day, so plants put out a lot of growth. It’s not lush; it’s a very solid growth. It’s very conducive to plant growth. And our winters are just terrible, so plants have to be tough. It’s actually been a very nice climate, being between the lake and the bay, our falls are very long, so the plants have a lot of time to really finish off and just go into the winter a little bit easier.”

It all helps Evergreen maintain the relationships and reputation that have kept it thriving for 150 years.

“Our goal is to be a propagator for any size nursery, basically,” Amos says. “We don’t supply everything, but our goal is to work with nurseries and give them liners that are going to take off, with that nice, heavy root system that they can work with easily.”

Explore the September 2014 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- John Ruter shares UGA's latest woody and herbaceous ornamental plant breeding projects

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- Get to know Kayela Aeppli

- HILA 2025 video highlights: John Gaydos of Proven Winners

- Q&A with Justin Bartlett

- Be the best choice