|

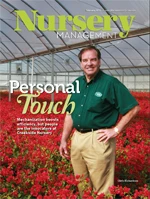

In 1992, Chris Richardson was operating a successful construction company. The economy was booming, and he had an impressive inventory of equipment and crews to run work. As an experiment, he put some container nursery stock on a couple of acres of pasture. In steady increments Richardson added acreage, and by the time Creekside Nursery was incorporated, he had 40 acres in production. The nursery now operates on 325 acres including 35 acres under cover.

With year-round planting, propagation and selling, the Creekside staff is always looking for ways to mechanize processes and reduce labor. “We switched from a pallet loading system to a conveyor loading system for faster, more efficient loading and delivery,” Richardson said. Plants are taken from the potting shed to a planting block via trailer. A conveyor belt transports new plantings from the trailer to the planting block. Conveyors are also used at the loading dock, where the conveyors are rolled into the delivery truck to eliminate excessive plant handling. “Minimizing the number of times that labor is needed to move a plant saves time and money,” Richardson said.

“This tunnel allows our employees to safely transport products and people to either side of the road without the dangers of crossing a busy road on a tractor while pulling trailers full of plants,” Richardson said. Product diversity To help keep up with the diverse product line, Creekside uses a live inventory system that allows its sales team – located across Texas – and the production team to stay on top of availability and communicate upcoming schedules. “Our production team can input specs, availability dates and quantities at any time of the day,” said Christan Fuqua, vice president of marketing. “When the sales reps enter orders, they can see the inventory and have current information. Communication from the field to the sales rep is key to selling success.” Creekside’s Specialty Ornamental program offers the newest plants with the best genetics, Fuqua said. “We test new products and search for products that adapt well to the many climates in Texas,” she said.

Richardson and his team encourage the sales staff to bring in ideas for new products. Other specialty products include xeriscape plants such as succulents and cactus, and a line of citrus with some varieties bred at Creekside by grower Scott Reeves. Recycling programs The nursery recycles its poly and containers. It contracts with a company that brings in a large baler for about a month. Creekside also recaptures rainwater and runoff. The nursery is designed so all runoff goes into 10 ponds. “Rainwater is the best water we get, while runoff from the blocks is the second. The groundwater is the least desirable water,” Richardson said. The nursery also uses composted trees and tree waste in its growing media. The practice started after Hurricane Ike felled lots of trees in the area. “Now we get tree waste from tree-trimming companies and people who clear land,” he said. The grower uses a tub grinder to regrind the trees into the right consistency. It’s then composted and mixed with pine bark. “We add out own micronutrients and fertilizer to the mix,” he said. “We’ve tweaked the process and we have a shrub mix and a tree mix.” For more: Creekside Nursery, www.creeksidenursery.com

|

Explore the February 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- John Ruter shares UGA's latest woody and herbaceous ornamental plant breeding projects

- Conor Foy joins EHR's national sales team

- Pantone announces its 2026 Color of the Year

- Syngenta granted federal registration for Trefinti nematicide/fungicide in ornamental market

- Get to know Kayela Aeppli

- HILA 2025 video highlights: John Gaydos of Proven Winners

- Q&A with Justin Bartlett

- Be the best choice

Richardson used his construction background to build a showplace nursery. Creekside has paved roads from the color houses to the loading dock and a graded facility to capture runoff.

Richardson used his construction background to build a showplace nursery. Creekside has paved roads from the color houses to the loading dock and a graded facility to capture runoff. A busy farm road splits the nursery, and workers had to cross the road with tractors and trailers filled with plant material. In 2005, Creekside designed an innovative solution and built a tunnel out of box culverts that runs beneath the road.

A busy farm road splits the nursery, and workers had to cross the road with tractors and trailers filled with plant material. In 2005, Creekside designed an innovative solution and built a tunnel out of box culverts that runs beneath the road. As part of the program, Creekside is offering a Sun Blazer series dwarf rose from Star Roses in a terra cotta pot for Mother’s Day sales.

As part of the program, Creekside is offering a Sun Blazer series dwarf rose from Star Roses in a terra cotta pot for Mother’s Day sales.