|

The nursery ships throughout North America, including the West, the Plains and the Midwest. “It also helps us control our inventory. The live data is a really great feature,” he said. Accuracy has improved by using the handhelds. “This system allows people who don’t know plants, the English language or Latin plant names to still pull the orders correctly,” he said. Plans are in the works to use the handhelds for onsite orders. “We’re trying to make it so our salespeople can use the handhelds to scan plants at the garden center and send in an order,” he said. For more: Bylands Nurseries, www.bylands.com. SBI Nursery Software, www.sbinursery.com. |

Explore the June 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- Dümmen Orange North America celebrating 25th anniversary in 2025

- Illinois Landscape Contractors Association changes name to Landscape Illinois

- 2025 Proven Winners Horticulture Scholarship applications now open

- ICL’s Gemini Granular herbicide now registered for use in California

- Eurazeo Planetary Boundaries Fund acquires Bioline AgroSciences

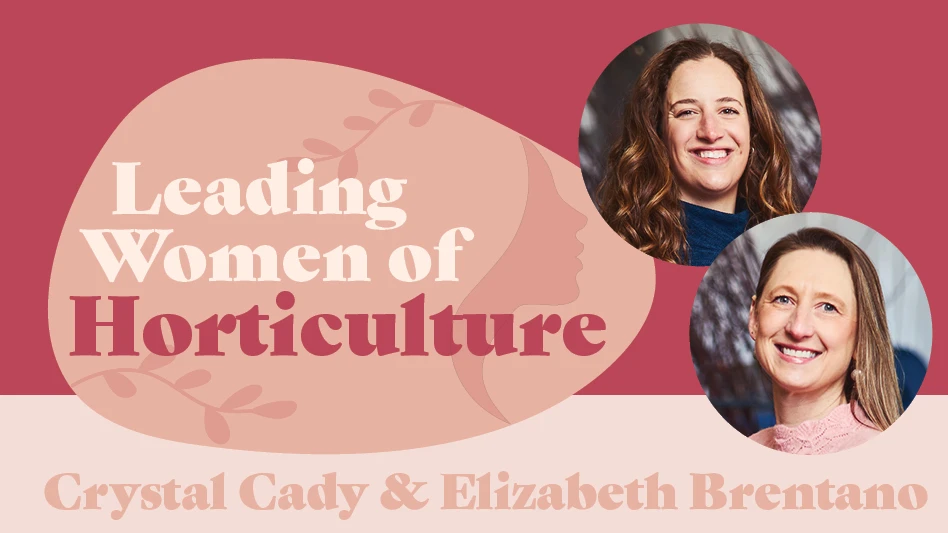

- The Leading Women of Horticulture

- Leading Women of Horticulture: Dana Massey, Plantworks Nursery

- Spring Survival Guide