|

The method has allowed the nursery to grow and sell trees that are often classified as “difficult to transplant,” such as oaks and pecans, Kim said. Native applications Fisher Hog Farms near Middletown, Mo., used RPM-produced trees and shrubs to create a vegetative environmental buffer. The buffer is made up of specially-designed plantings that help improve air and water quality around a livestock facility. The pork operation won the 2011 Missouri Environmental Steward Award for “demonstrating a firm commitment to safeguarding the environment and the communities that surround them.” For wetland restoration, the nursery developed a four-step Walk-A-Way system to achieve high survivability rates, since most of these projects “get little or no attention after planting,” Kim said. The Walk-A-Way system starts with ground preparation (plowing, disking and berm creation) in June or July; cover crop establishment in August or September; tree establishment in October or December; and mat placement (weed barrier and moisture retainer) and fertilization in April or May. The growth rate of RPM hardwoods is vastly accelerated, Kim said. The nursery’s trees achieve 3-5 feet of growth during the first year, putting the trees beyond the easy reach of browsing deer, floodwaters and sunlight competition. “Take our RPM white oak, for instance. It fruits in the fourth year, which means better reproduction rates and more wildlife food,” she said. Natives are an excellent choice for rain gardens or bioswales, which require the use of deep-rooted plants, Kim said. The nursery installed its own working rain garden in spring 2008. “The deep-rooted native plants and sunken profile of the rain garden really help absorb stormwater, as well as surface water runoff and reduce erosion,” Kim said. “The rain garden has solved our problem with standing water on our front lawn. It also adds a beautiful feature that attracts songbirds.” Other applications for RPM-produced natives include agroforestry, wildlife habitat creation and restoration, urban forestry, erosion control and biomass production. “Bioremediation is gaining speed in the Rust Belt,” Wayne said. “Project managers are looking for tough species that not only tolerate poor soil conditions, but help clean up the soil.” A new natives niche As the nursery sold native plants to restoration and conservation projects, Kim saw a need for native wildflowers and added that segment to production. “After a downturn in the bare-root seedling market two or three years ago, wildflowers has become a successful program for us,” she said. The wildflowers follow the tree and shrub production in the propagation houses. The nursery is growing straight native species and no native cultivars. Wildflowers are available in a 1-gallon container, and the nursery is getting more interest from retailers for this program. For more: www.fknursery.com. Photos by Bill Sawalich, Barlow Productions |

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the June 2011 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- Dümmen Orange North America celebrating 25th anniversary in 2025

- Illinois Landscape Contractors Association changes name to Landscape Illinois

- 2025 Proven Winners Horticulture Scholarship applications now open

- ICL’s Gemini Granular herbicide now registered for use in California

- Eurazeo Planetary Boundaries Fund acquires Bioline AgroSciences

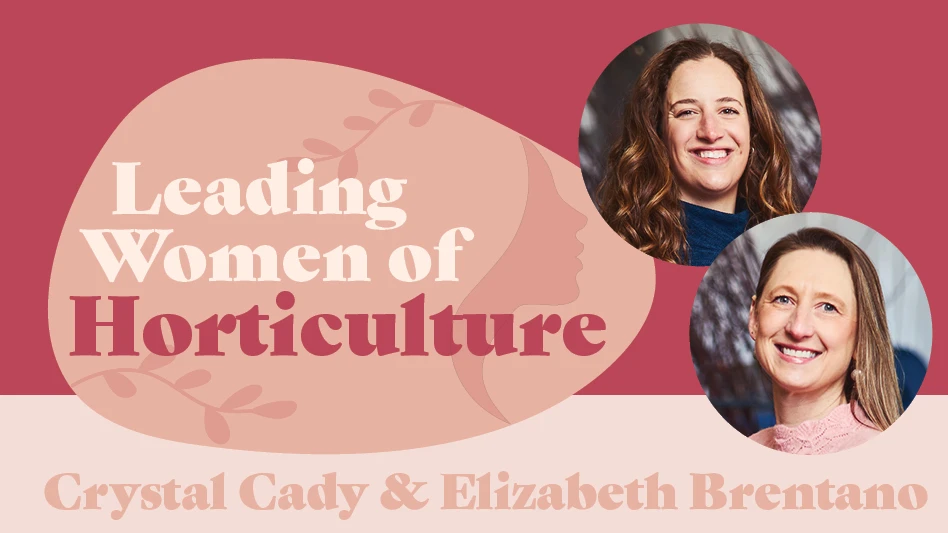

- The Leading Women of Horticulture

- Leading Women of Horticulture: Dana Massey, Plantworks Nursery

- Spring Survival Guide