The

“They had enough visitors to their properties and they were turning a geranium cutting in 15-16 days,” Maartense says. “An average American company was doing it in 24-25 days. Everybody asked ‘why?’ And they attributed it to the AeroNT product.”

1 | What are the advantages to the AeroNT?

It’s a bonded media plug, like some other products out there, but it’s different. We use a bonding agent to bond a standard growing mix — that’s a proprietary mix

2 | What makes the AeroNT different?

Our product is inherently more airy and porous than a lot of other products that are out there. It dries out faster than a lot of other products out there. That gives the grower more opportunities in the rooting cycle to “attack” the plant. Fertigate, address issues. By being dry, we eliminate a lot of fungal problems that could occur.

3 | What types of plants are a good fit for the AeroNT?

The full gamut across the board. Our main customer base is the unrooted cutting grower. As well as cuttings for woody perennials and woody ornamentals, people who are sticking cuttings into a soilless mix. We’re not too focused on the seed growers; it’s more of a cutting-based clientele.

4 | What sizes are available?

The smallest cell we do is a 210, which is roughly 1 centimeter across. Then we go from a 102, which is pretty standard unrooted cutting size, right up to a 32-count, 50-mm plug for the larger, more leafy plant material.

5 | How can growers get started with AeroNT plugs in their production system?

Basically, we prefill plastic trays, shrink wrap them, palletize them and send them to a grower. They are moist; they are ready to stick. They are pre-dibbled. So the grower can take it off the pallet and take it to their sticking line, whether that’s automated or on the bench and they can stick into it immediately.

The premise behind our system is we make a plug, topdress that plug with a fine media that has no binding agent in it, and once the grower sticks the cutting in the hole, when they water it the first time that loose substrate on top closes around the stem. That gives the grower faster closure, faster callous and in turn, a faster rooting time and faster turnaround. Most of our growers are shaving a week off their propagation times, if not more.

6 | How does it speed up the rooting process?

Because we add a binding agent to a normal substrate, our end result is very porous. So we have a lot of air in the plug. Because we inherently stay porous, the roots have the ability to get through the plug a lot easier. If you take a paper pot plug, where it’s a loose media, what happens in the first couple of watering cycles is all the fines that are in that peat go down to the bottom of the plug. So the bottom of the plug stays wet and the top of the plug dries out. Whereas our product dries out very uniformly. The premise is once you start drying that plug out, you force the roots to look for moisture and food. That gives you a very quick, uniform rooting in that plug.

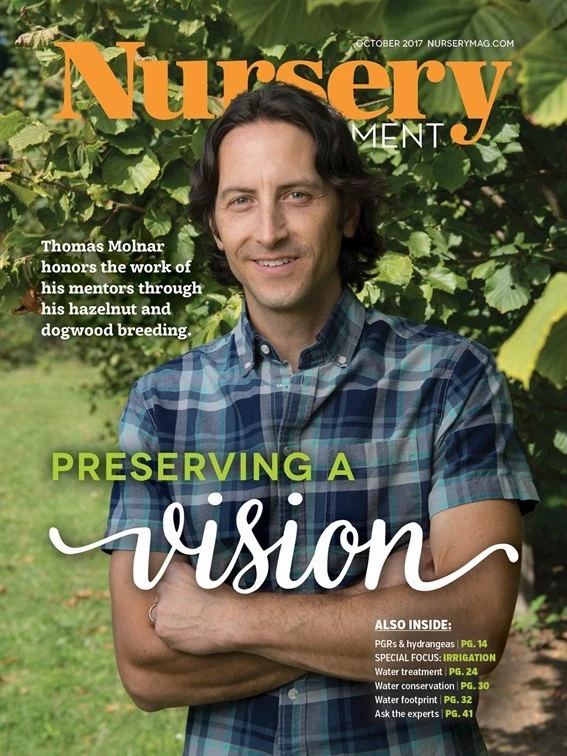

Explore the October 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- The HC Companies, Classic Home & Garden merge as Growscape

- Eason Horticultural Resources will now officially be known as EHR

- BioWorks receives EPA approval for new biological insecticide for thrips, aphids, whiteflies

- Ellen Mackenbach-Lakeman appointed new CEO of Dümmen Orange

- Southern Garden Tour sets 2025 dates for trial garden open houses

- New book explores plants that thrive in Rocky Mountains

- American Floral Endowment establishes Herman Meinders Memorial Tribute

- These companies are utilizing plastic alternatives to reduce horticultural waste