Adobe Stock

Weed control is a leading cultural problem facing nursery growers. There are weeds for all places in all seasons, including winter annuals, summer annuals, biennials, perennials, grasses, sedges, and broadleaves. If one type is eliminated, another will take its place.

Weeds must be controlled because they can cause direct or indirect reductions in crop growth or quality and because they are aesthetically objectionable. They directly compete with crops for water, nutrients, and light. Some weeds affect the growth of woody plants by producing chemicals that stunt their growth. Weeds indirectly affect crops or landscapes by harboring rodents that may eat the bark of trees and shrubs, causing severe damage or death. Many nursery practices, such as pruning, are complicated by the presence of weeds. Also, weeds slow air movement, which may result in a higher incidence of foliar diseases or frost damage.

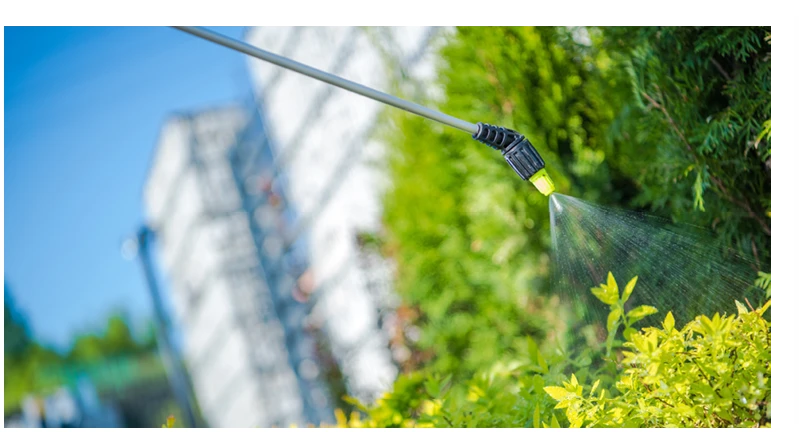

For this issue, we’re focusing on sprayers.

In calibrating a sprayer, the speed and pressure at which the sprayer is operated, the nozzle being used, and the height at which the nozzle is held (which controls the width of the band sprayed) must be kept constant.

The parts of the spray system include the pump, pressure regulator, pressure gauge, screens (strainers), and nozzles. Many herbicides are made up of particles suspended in the spray solution. They cause a lot of abrasion and wear on piston pumps. The best pumps to use with these products are diaphragm or centrifugal pumps because they will last much longer than other pumps. Pressure regulators are needed to maintain a constant pressure during application. Herbicides should be applied at 15 to 40 psi. The pressure gauge makes it possible to reset the pressure regulator from one operation to another.

A 50-mesh in-line strainer should be used to prevent nozzle clogging, especially when wettable powders are being applied. Strainers with check valves are available that require 5 psi pressure to open them. This prevents the dripping of the spray solution that is in the system between the shutoff valve and the tip. The check valve in the strainer closes immediately when the shutoff valve is closed.

Sprayer nozzles

The nozzle tip is a critical component of a sprayer. Although relatively inexpensive, this part of the system must not be neglected. The nozzle affects the flow rate, breaks up the mixture into droplets, and disperses the droplets in a specific pattern. The proper nozzle must be selected for the desired job. No single nozzle can meet all spraying needs.

When buying nozzles, the grower must choose from a variety of angles and spray rates. Nozzles with angles ranging from 65 to 130 degrees are available for applying herbicides. Wide-angle nozzles can be operated close to the ground to minimize drift. Narrow-angle nozzles should be used where high clearance over some plants may be needed.

The flow rate of nozzles is measured under standardized conditions, such as a tractor speed of 4 miles per hour and a pressure of 30 psi. The rate of spray applied per acre by a particular nozzle can be increased by driving slower or by increasing the pressure. The rate of spray applied per acre can be decreased by driving faster or by decreasing the pressure.

An example of a nozzle used for applying herbicides is an 8004, which provides a spray angle of 80 degrees and has an output of 0.4 gallons per minute at 40 psi.

Different types of nozzles are commonly used to apply herbicides in nursery or Christmas tree plantings.

Flat-fan nozzles disperse droplets in a fan shape. The edges of the flat fan pattern have lower spray volumes than the center of the pattern, so they should be used only in combination on spray booms. To get uniform distribution of the herbicide across the width of the boom, the patterns of adjacent nozzles should overlap by 40 to 50 percent. With a 20-inch nozzle spacing, the proper overlap would be 8 to 10 inches. To get uniform spray patterns from flat fan nozzles, a pressure of at least 30 psi is required.

Low-pressure flat fan nozzles are for those who want to use lower pressures, as is often the case with backpack sprayers. They are designed to be operated at 10 to 25 psi. The lower operating pressures and larger orifices on these nozzles reduce clogging and provide larger spray droplets that reduce drift. A low-pressure flat fan nozzle is designated with the letters LP after the number (8004 LP). Flat fan and low-pressure flat fan nozzles are recommended for use only on boom sprayers. The nozzles on a boom should all be the same type and size to ensure even distribution. They should never be used for making band applications because, when used alone, the spray distribution pattern is very uneven.

Even-spray nozzles are used to make band applications. They are similar to flat fan nozzles but apply the herbicide uniformly across the entire pattern. Even-spray nozzles are available with 80- or 95-degree spray angles. Typical working pressures range from 20 to 40 psi. The width of the band can be adjusted by raising or lowering the nozzle. This nozzle should not be used on a boom for broadcast spraying. Even-spray nozzles are identified by the letter E after the number (8004 E).

Flooding fan nozzles produce a wide, flat spray pattern. The wide spray angle (110 to 130 degrees) allows wider nozzle spacing and lower boom heights. The larger orifice produces large droplets and makes the flooding fan nozzle resistant to drift and clogging. Optimum broadcast coverage is achieved by overlapping spray patterns 100 percent to obtain double coverage. Pressures of 10 to 30 psi are commonly used.

Off-center nozzles produce a pattern that is approximately half that of a flat fan nozzle. They are used for directing a spray at the base of a row of plants without getting the spray on a cover crop between the rows. Off-center nozzles are identified by the letters OC before the number designating rate of output (OC 04).

Nozzles are available in a variety of materials. Brass and aluminum are the least expensive, but the metal is soft and wears quickly when abrasive materials like wettable powders are used. Stainless steel and hardened stainless steel cost three to five times more than brass but wear 19 to 77 times longer. The cost, uniformity, and durability of nylon nozzles vary with the quality of the nylon used to make them. They can be as uniform and durable as stainless steel at one-half the cost, or they may be quite variable in rate of spray output. The operator should consult with the supplier before buying nylon nozzles. An excellent combination of products is a nozzle with a nylon body and a stainless steel orifice. It provides the durability of stainless steel with the low cost of nylon.

To prevent plugging and excessive wear of nozzles, screens should always be used to remove large particles from the spray mixture. Check the manufacturer’s recommendation for the nozzle to be used. A general recommendation is to use a 50-mesh screen. Screens with ball check valves are recommended for use when applying postemergence herbicides because they prevent dripping from the nozzle after the control valve has been closed.

A sprayer remains accurately calibrated only as long as the openings of the nozzles remain unchanged. As nozzles wear, the openings become larger and the rate and uniformity of herbicide applied become more variable. To minimize these problems, the operator should buy high-quality nozzles, inspect them regularly, and replace them as needed. To clean a clogged nozzle, use compressed air or a soft-bristled brush, such as a toothbrush. Never use wire or a nail because the nozzle orifice can be easily damaged.

Tractor-mounted sprayers

Many configurations and systems can be used with tractor-mounted sprayers. Centrifugal or diaphragm pumps are recommended. They can have their own engines for power or can be run off the PTO of the tractor. The tanks range greatly in size and may be mounted in the back or front of the tractor. Spray booms or individual nozzles may be mounted in the back, front, under the belly, or on the foot plates of the tractor. Flat booms or drop nozzles may be used. The system that is best for a particular situation will depend on the herbicide being used and the growth habit and size of the plants being grown.

Hand-carried sprayers

The most common hand-carried sprayers are the 2- or 3-gallon compression type and the continuous pump backpack sprayers. Either can be used to spray a small or irregular area like a landscape bed without worrying about calibration. Simply add the amount of herbicide needed to treat the area to enough water to spray uniformly over the area at least twice. Marker dyes also can be added to the spray solution to indicate the uniformity of application. The dyes break down in sunlight and disappear within 3 or 4 days.

For treating larger areas, sprayers must be calibrated. Backpack sprayers should be used because the pump can be operated continuously to maintain a uniform pressure. Sprayers with diaphragm pumps are far superior to sprayers with piston pumps because piston pumps wear out faster and tend to leak. Because these sprayers are mounted on the backs of the applicators, any leaks result in considerable direct exposure to the spray solution.

Some backpack sprayers have pressure regulators built into them. They can be used with no further adaptation. Sprayers without pressure regulators need some adaptation to make them more suitable for herbicide application. A pressure gauge is essential for uniform application. It should be mounted on the tank side of the shutoff valve so the tank pressure can be continuously monitored. If the gauge is mounted on the nozzle side of the shutoff, it will show the tank pressure only when the valve is open. For optimum control, a pressure regulator also should be inserted into the system somewhere between the pressure gauge and the nozzle.

Shutoff valves of some hand sprayers are often too slow to prevent dripping from the nozzle after the valve is closed. This can cause serious problems when nonselective herbicides such as Roundup Pro are being used. Such valves should be replaced with a quick, positive pressure shutoff valve or strainers with check valves.

A two- or four-nozzle boom can be adapted to apply herbicides to large plantings or turf.

Calibrating a sprayer

After a tractor-mounted or backpack sprayer has been customized to meet particular needs, it should be calibrated according to the following instructions:

On an area that best represents the average topography for the area to be sprayed, measure and mark off the calibration distance that coincides with the band width, if band applying, or with the nozzle spacing (width covered by a single nozzle) if broadcast applying (see Table 1).

Calibration distance____________ feet

Fill the sprayer with water only and record the number of seconds required to travel the calibration distance at a comfortable, steady speed. With a tractor-mounted sprayer, note and record the engine rpm and the gear selection so that the same speed is used during calibration and application. For backpack sprayers, it is important that the person making the application is the person that calibrates the sprayer, because the calibration is based on that person’s pace.

Gear ___________ rpm____________ time in seconds___________________

While maintaining the selected application pressure, collect the spray output from one nozzle for the same number of seconds needed to travel the calibration distance.

Amount of water collected in fluid ounces _________________________________

The number of fluid ounces collected equals the gallons per acre (GPA) output of the spraying system.

Example 1: With a 32-inch band, if it took 28 seconds to travel 127 feet, collect the nozzle discharge for 28 seconds. 16 ounces collected equals a system output of 16 GPA.

Example 2: With 20-inch nozzle spacing, if it took 35 seconds to travel 204 feet, collect the discharge of one nozzle for 35 seconds. 20 ounces collected equals a system output of 20 GPA.

If using a boom, repeat Step 3 twice more, collecting water from a different nozzle each time. The average number of ounces collected for each of the three nozzles is equal to the gallons of water applied per acre for that boom, speed, and pressure. If the difference in output of any of the nozzles tested varies more than 10 percent from the others, check all of the nozzles on the boom and replace as needed.

To determine the amount of chemical to add to the spray tank, divide the capacity of the tank by the number of gallons of water applied per acre to determine the area that can be covered with a tankful of spray.

Example 1: 3 gal tank ÷ 16 GPA = 0.188 acres covered per tank.

Example 2: 200 gal tank ÷ 20 GPA = 10 acres covered per tank.

Multiply the application rate of the product per acre times the area covered per tank. Add that amount of chemical to the sprayer tank.

Example 1: 2 qt per acre = 64 fl oz per acre x 0.188 acre per tank = 12 fl oz per tank.

Example 2: 5 lb per acre = 80 oz per acre x 0.188 acre per tank = 15 oz per tank.

Example 3: 2 qt per acre x 10 acres per tank = 20 qt, or 5 gal per tank.

Mixing herbicides

Concentrated herbicides should never be poured directly into an empty tank. Add one-half the necessary water to the tank, then the herbicide concentrate, and finally the remainder of the water. Mix the spray solution by operating the sprayer with the control valve in the closed position for a few minutes.

Never allow a sprayer with mixed chemicals to stand without agitation. Heavy wettable powders may clog nozzles and settle into the corners of the spray tank, becoming very difficult to remove.

When applying combinations of herbicides, add them to the tank in this order: wettable powders, flowables, water solubles, adjuvants, and emulsifiable concentrates. Constant agitation is important when combinations of pesticides are in a tank.

When using backpack sprayers, thoroughly mix the chemicals in a bucket with a pour spout; then pour the mixture into the sprayer. It is difficult to get proper mixing if the chemicals are added directly to the sprayer.

Herbicide compatibility

Two pesticides or a pesticide-fertilizer mixture sometimes separates when combined in a sprayer. Including a type of surfactant called a compatibility agent, or adjuvant, may help get them mixed. Compatibility agents available on the market include Compex, Co-mix, and Unite.

When the compatibility of the materials to be mixed in the tank is uncertain, the following jar test can be used to determine how well they mix:

Put 1 pint of water or chosen fluid fertilizer in each of 2-quart jars.

Using rates proportional to those that will be used in the field, combine the chemicals to be mixed in one of the 2-quart jars.

To the other quart jar first add a compatibility agent (0.5 teaspoonful) to water or fluid fertilizer; then add the herbicide mixture.

Close both jars and mix contents by inverting jars 10 times.

Inspect jars immediately.

Allow jars to stand undisturbed for 30 minutes and inspect them again.

If both mixtures remain uniform for 30 minutes, the combination may be used. If the mixture with the compatibility agent stays mixed but the one without the compatibility agent does not, be sure to use the compatibility agent in the spray tank.

Should either mixture separate after 30 minutes but remix readily with 10 jar inversions, the mixture can be used if good agitation is maintained in the tank. If nondispersible oil, sludge, or clumps of solids form, the mixture should not be used.

If tank-mixed chemicals are compatible, time and labor can be saved by applying herbicides in combination with fertilizers. When such mixtures separate, clogged tanks and lines and uneven, deficient, or excessive rates of application result. This can cause crop injury, poor weed control, and residue problems in addition to the expense and disposal required for mixtures that cannot be used.

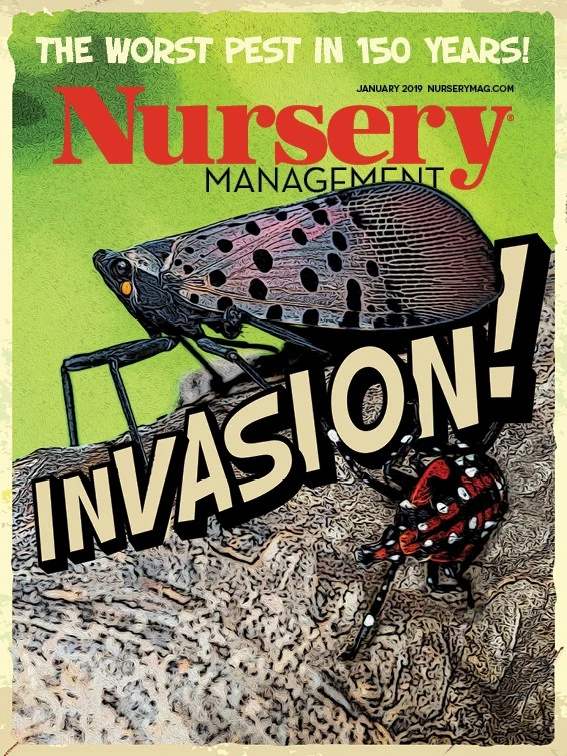

Explore the January 2019 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- These companies are utilizing plastic alternatives to reduce horticultural waste

- NewGen Boxwood added to Proven Winners ColorChoice line

- Terra Nova releases new echinacea variety, 'Fringe Festival'

- American Horticultural Society names winners of 2025 AHS Book Awards

- Nufarm announces unified brand

- American Horticultural Society announces winners of 2025 Great American Gardeners Awards

- Shifting the urban environment

- The Growth Industry Episode 3: Across the Pond with Neville Stein