Photos: Vanessa Rivas

Windmill Nursery is family-owned with five generations of nursery experience. Todd Ellefson leads as the company’s president and has been in upper-division management since 2003. Since then, Windmill Nursery has doubled in size and services a third of the U.S. Its customers are garden centers, rewholesale customers and landscape contractors. Ellefson is the great-great-grandson of John Wight, who founded Wight Nurseries in the 1800s.

In the late summer of last year, Windmill Nursery made the decision to bring in Van Belle Nursery’s innovations. With Van Belle’s Bloomin’ Plants, RocketLiners, JetPack plugs and FloGo pot-less shipping, Windmill Nursery’s product diversity has seen an increase.

The Canadian company’s RocketLiners are designed to finish a 2-, 3- or 5-gallon container in a single season. RocketLiners are propagated using Van Belle’s patented trays, which produce robust inputs with better root training, more surface area and greater fresh root mass. Ellefson says the product gets them to market faster.

“With us being in the deep south, a lot of these varieties we’re bringing in, it’s better for them to have the Canadian chill hours versus south Louisiana chill hours,” he says. “January for us, it’s like an early spring. For a lot of people, it’s the middle of winter, but January, February, the plant just kind of explodes out of dormancy because it’s been in such a deep sleep compared to the product that we hold over winter.”

He estimates Windmill Nursery uses about 15 different varieties of Van Belle’s Bloomin’ Easy Plants, from Toy Soldier Oakleaf Hydrangea to distylium and loropetalum.

Ellefson says having these in their production plan makes for “a complementary mix.” “[We take] product that we maybe haven’t had success rooting, growing and use the RocketLiners to plant in the winter to get to market fast in spring.”

The company ships young plants de-potted in recyclable boxes, which they call the FloGo pot-less shipping system, and it has been working well for Windmill Nursery.

Van Belle’s innovations have given Windmill Nursery’s sales team more to talk about and sell, as well as keeping the nursery’s customers’ needs met and valued.

“I think the big thing is product diversity,” Ellefson says. “That’s a value to the customer. And yeah, the diversity is pretty big.”

One thing that he says has been impactful for him to see is customers acceptance in taking on new genetics, as well as a new brand.

“It just isn’t as common down here,” he says. “So, to introduce that and have our customers have some interest in the product as well shows the acceptance of them to introduce new product to their customers.”

He explains that adding a new line can be a big deal to introduce to an independent retailer or wholesaler.

“They’re just potentially introducing confusion,” he says. “But there’s a willingness to introduce something that may be potentially better.

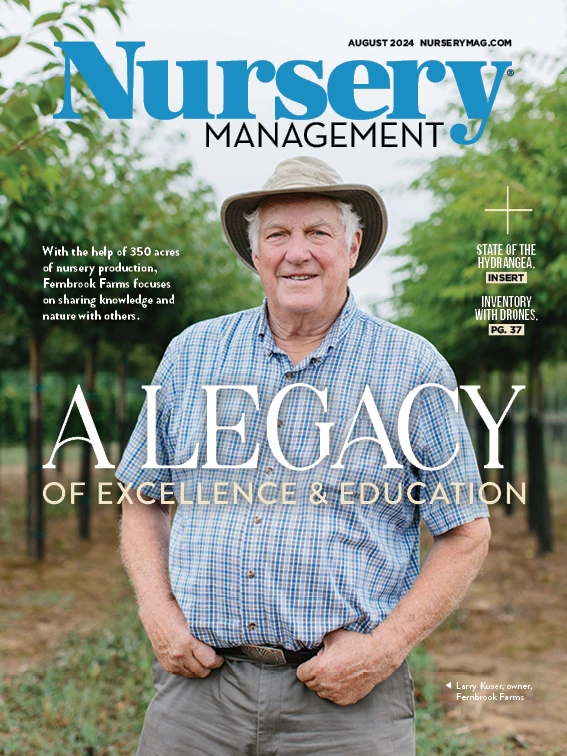

Explore the August 2024 Issue

Check out more from this issue and find your next story to read.

Latest from Nursery Management

- The HC Companies, Classic Home & Garden merge as Growscape

- Terra Nova releases new echinacea variety, 'Fringe Festival'

- Eason Horticultural Resources will now officially be known as EHR

- BioWorks receives EPA approval for new biological insecticide for thrips, aphids, whiteflies

- Ellen Mackenbach-Lakeman appointed new CEO of Dümmen Orange

- The Growth Industry Episode 3: Across the Pond with Neville Stein

- Southern Garden Tour sets 2025 dates for trial garden open houses

- New book explores plants that thrive in Rocky Mountains